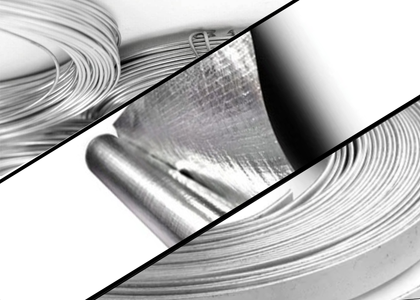

In the fast-evolving industrial and technological landscape, aluminum wires, strips, insulation products are indispensable. Their unique properties and diverse applications make them essential components in industries such as construction, energy, automotive, and electronics. This blog explores their significance, properties, and applications in detail, emphasizing their growing importance in modern infrastructure.

Aluminum Wires: A Foundation for Electrical Systems

Aluminum wires have revolutionized electrical systems due to their lightweight nature, high conductivity, and cost-efficiency. These wires are made from aluminum, a material known for its excellent strength-to-weight ratio, making it ideal for various applications.

Key Properties of Aluminum Wires

- Lightweight: Aluminum wires are significantly lighter than their copper counterparts, making them easier to install and handle in large-scale projects.

- High Conductivity: Although slightly less conductive than copper, aluminum wires are sufficient for most electrical applications while offering substantial cost savings.

- Corrosion Resistance: Aluminum forms a natural oxide layer that protects it from rust and environmental damage, enhancing durability.

- Affordability: Aluminum is more cost-effective than copper, making it an attractive choice for budget-conscious projects.

Applications of Aluminum Wires

- Power Transmission: Aluminum wires are extensively used in overhead power lines and transmission systems due to their lightweight nature and high conductivity.

- Building Wiring: They are commonly found in residential and commercial wiring, especially for large current-carrying cables.

- Electronics Manufacturing: Aluminum wiring is used in electronic components for efficient energy transfer.

Aluminum Strips: The Backbone of Energy Systems

Aluminum strips are flat, thin sections of aluminum that are used in various industrial applications. Their flexibility, thermal conductivity, and corrosion resistance make them an essential material in manufacturing and energy systems.

Benefits of Aluminum Strips

- Versatility: Aluminum strips can be customized into various shapes and sizes, making them suitable for diverse applications.

- Thermal Conductivity: These strips are excellent heat conductors, making them ideal for cooling and heating systems.

- Recyclability: Aluminum is highly recyclable, making aluminum strips an eco-friendly option.

- Durability: The strips can withstand high temperatures and pressures, making them suitable for demanding environments.

Applications of Aluminum Strips

- Transformers: Aluminum strips are widely used in the windings of transformers, ensuring efficient energy transfer.

- Radiators and Heat Sinks: Due to their thermal conductivity, they are employed in radiators and cooling systems in vehicles and electronics.

- Packaging Industry: Aluminum strips are used in the packaging industry for their malleability and resistance to moisture.

Insulation Products: Safety and Efficiency in Wiring

Insulation products play a crucial role in ensuring the safety and efficiency of electrical and energy systems. These products prevent heat loss, reduce energy waste, and protect equipment from electrical faults and thermal damage.

Types of Insulation Products

- Electrical Insulation: Used to encase wires and cables, providing protection from electrical currents and reducing the risk of short circuits.

- Thermal Insulation: Used to retain heat in systems like HVAC and industrial boilers, improving energy efficiency.

- Acoustic Insulation: Used in buildings and vehicles to reduce noise levels and improve comfort.

Advantages of Insulation Products

- Energy Efficiency: By preventing heat loss and electrical leakage, insulation products enhance overall system efficiency.

- Safety: They protect users and equipment from electrical shocks, overheating, and fire hazards.

- Durability: High-quality insulation products are designed to withstand harsh environments and prolonged use.

Applications of Insulation Products

- Electrical Systems: Used in wiring, transformers, and circuit boards to prevent energy loss and ensure safe operation.

- Construction: Insulation products are used in walls, roofs, and floors to enhance energy efficiency in buildings.

- Automotive Industry: They are applied in vehicles to improve energy efficiency and thermal management.

The Synergy Between Aluminum Wires, Strips, and Insulation Products

When combined, aluminum wires, strips, and insulation products create robust and efficient systems suitable for modern infrastructure. Each component contributes to enhancing energy efficiency, reducing costs, and improving system reliability.

Why This Combination Works

- Complementary Properties: Aluminum’s conductivity and lightweight nature pair well with insulation products’ protective capabilities, ensuring optimal performance.

- Cost-Effectiveness: Using aluminum materials along with efficient insulation reduces overall project costs without compromising quality.

- Eco-Friendliness: Aluminum’s recyclability and insulation products’ energy-saving properties make this combination environmentally sustainable.

Environmental Benefits of Aluminum and Insulation

In an era of environmental consciousness, aluminum wires, strips, and insulation products stand out for their eco-friendly attributes.

- Recyclability of Aluminum: Aluminum is 100% recyclable without any loss in quality, making it a sustainable choice for manufacturers.

- Energy Savings: Insulation products reduce energy waste, lowering the carbon footprint of buildings and systems.

- Reduced Resource Consumption: The durability of these materials minimizes the need for frequent replacements, conserving resources.

Choosing the Right Aluminum and Insulation Products

Selecting high-quality materials is crucial for ensuring the longevity and efficiency of any project. Here are a few tips for making the right choice:

- Assess Your Needs: Determine the specific requirements of your project, such as conductivity, thermal resistance, or size.

- Check Quality Standards: Ensure that the products meet industry standards and certifications for safety and performance.

- Partner with Trusted Suppliers: Work with reputable manufacturers and suppliers to get reliable products and services.

- Consider Long-Term Costs: Focus on durability and efficiency rather than just initial costs to achieve better value over time.

Conclusion

The importance of aluminum wires, strips, insulation products in modern applications cannot be overstated. From enhancing energy efficiency to reducing environmental impact, these materials play a vital role in shaping sustainable and reliable systems. Their versatility, durability, and affordability make them indispensable in industries ranging from construction to electronics.

Investing in high-quality aluminum and insulation products ensures long-term performance and cost savings. As the demand for efficient and eco-friendly solutions continues to rise, these materials will remain at the forefront of technological and industrial advancements.